WHAT IS OUTDOOR PLASTIC WOOD?

The product can be applied to:

- Floor tiling, wall tiling, ceiling tiling.

- Making fences, gates, sun shields.

- Decorate balconies, gardens, and landscapes.

- Construction of pergola, flower trellis.

Depending on each product line, type of plastic wood (regular, Polymer coated, ASA coated), brand, size and accompanying costs such as: installation costs, accessories, labor, plastic wood ranges from 143.000 VND. – 510.000 VND/meter long.

According to Dr. David Grewell, Purdue University (USA): "WPC is a sustainable and environmentally friendly material, contributing to minimizing the negative impact on the environment of the construction industry."

Wood-plastic Composite

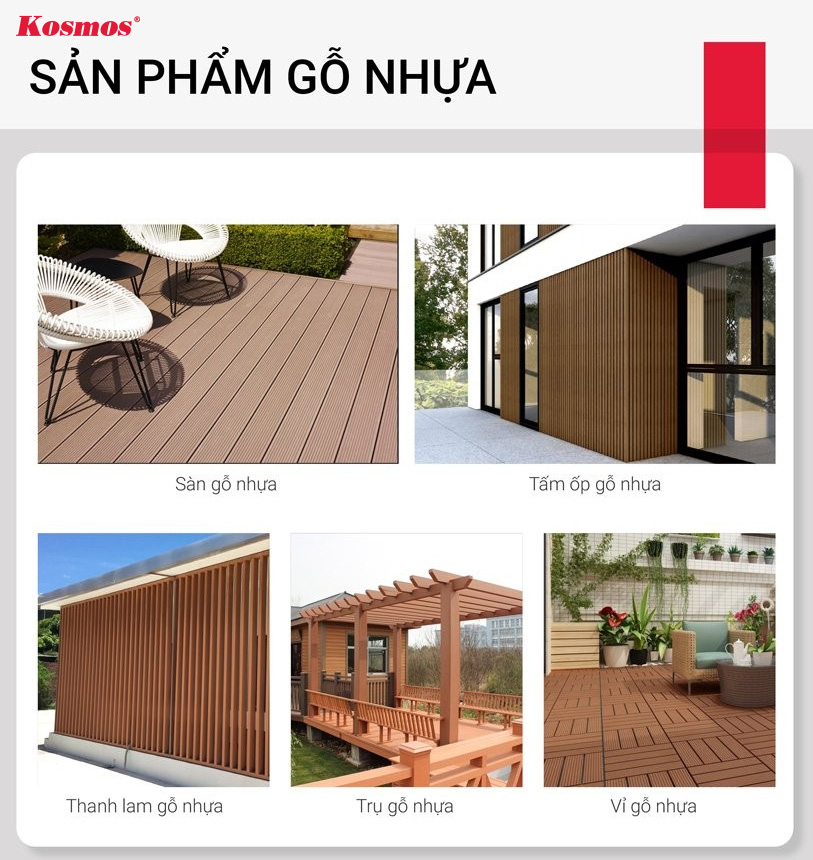

With a variety of products from flooring, cladding, decorative louvers, pergola posts, etc. Kosmos offers customers perfect choices for their exterior spaces.

Warranty policy for wood-plastic composite

Product warranty conditions

- 01 Corrosion by termites, warping, cracking, deformation when properly installed.

- 02 Technical defect due to manufacturing process.

- 03 Warranty period: 5 years

Out of warranty coverage

- 01 Quality problems due to wrong shipping and construction.

- 02 Due to the impact of natural disasters and other force majeure circumstances.

- 03 Damage caused by user error, due to improper maintenance.

- 04 No longer in the warranty period as above.

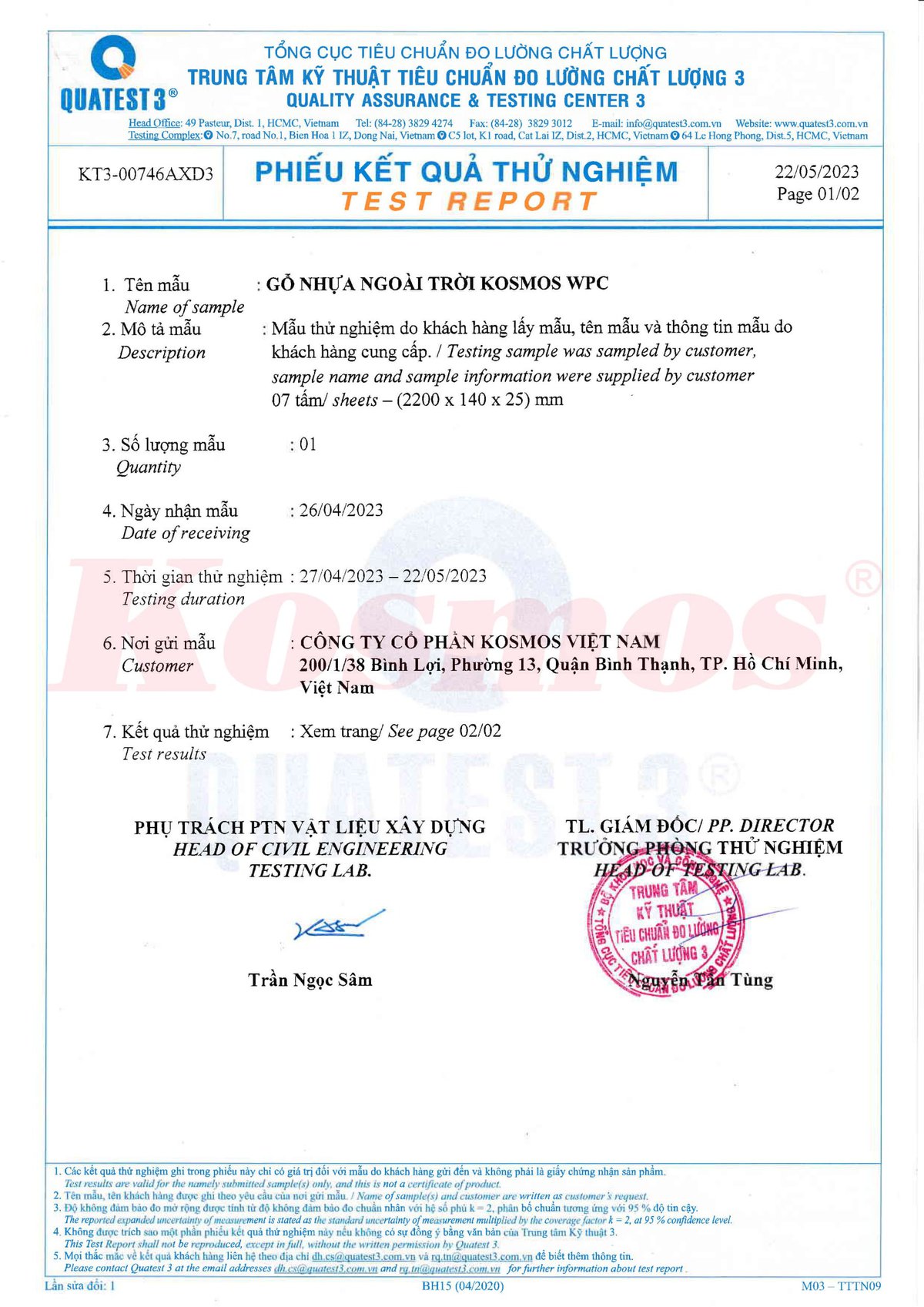

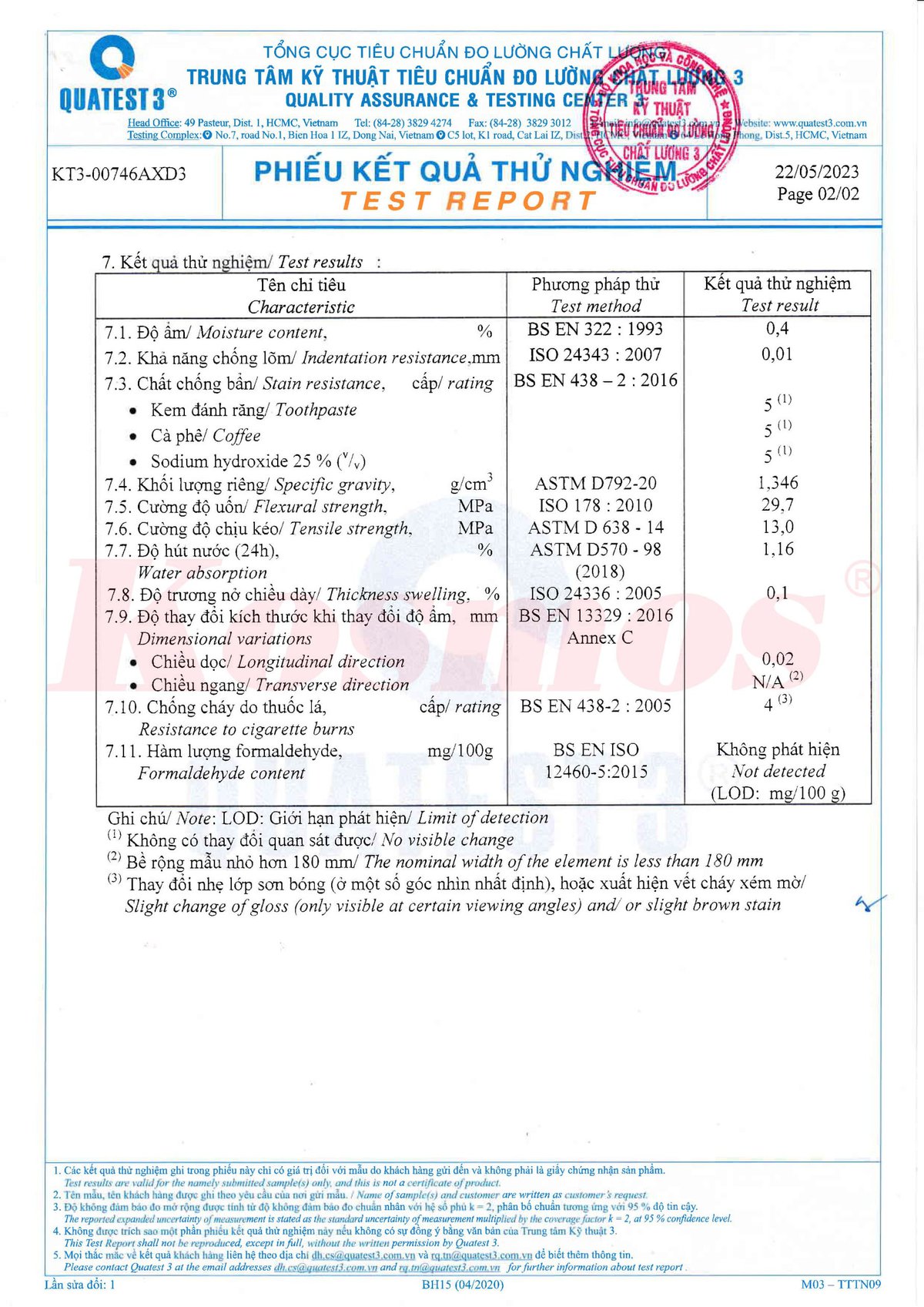

Quality certification

International standard quality

International standard quality

Product

View and download

Catalogue

View and downloadGet product quote

Please choose retail or agent quote type below!

Outdoor Plastic Wood Newsletter

Instructions for cleaning outdoor plastic wood floors properly and quickly

How to use 2D wood grain to limit color fading?

What is outdoor plastic wood? Structure, classification, advantages and disadvantages, applications

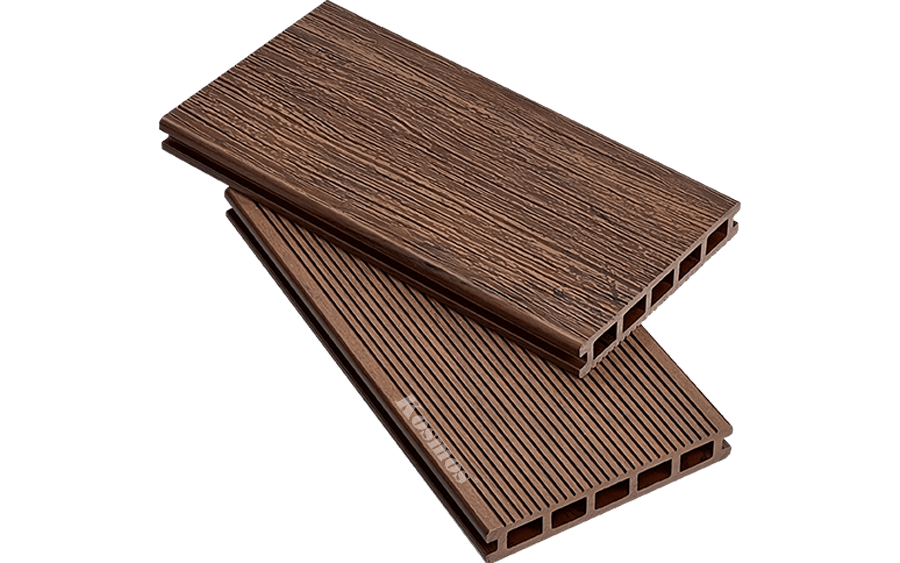

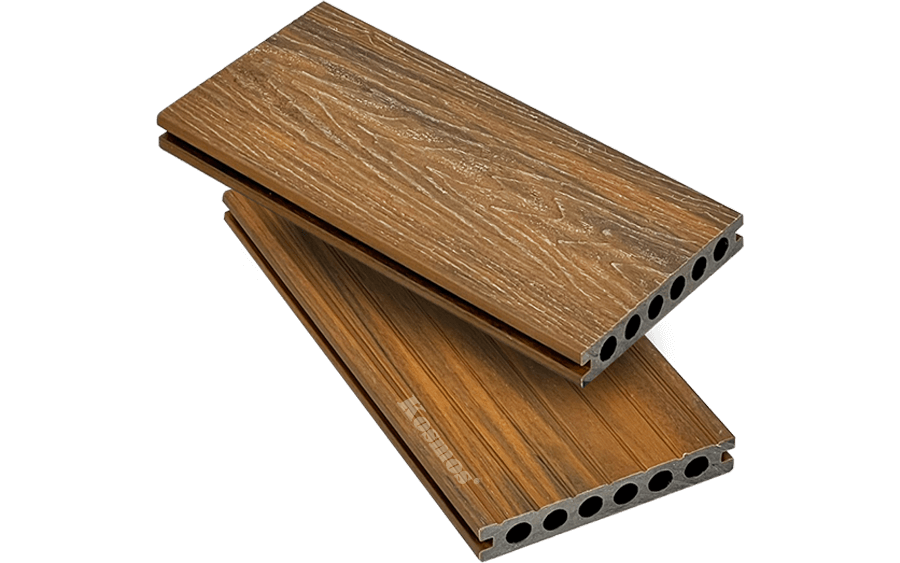

Outdoor plastic wood is a product made from synthetic materials between plastic and wood pulp, combined with many accompanying additives (eg: adhesives, colorants, antioxidants, ultraviolet ray absorbers). purple, mold inhibitors, etc.). Extrusion technology has produced many product lines from this material such as:

- Floor bar.

- Cladding.

- Blue bar.

- Pillar.

- Blister,…

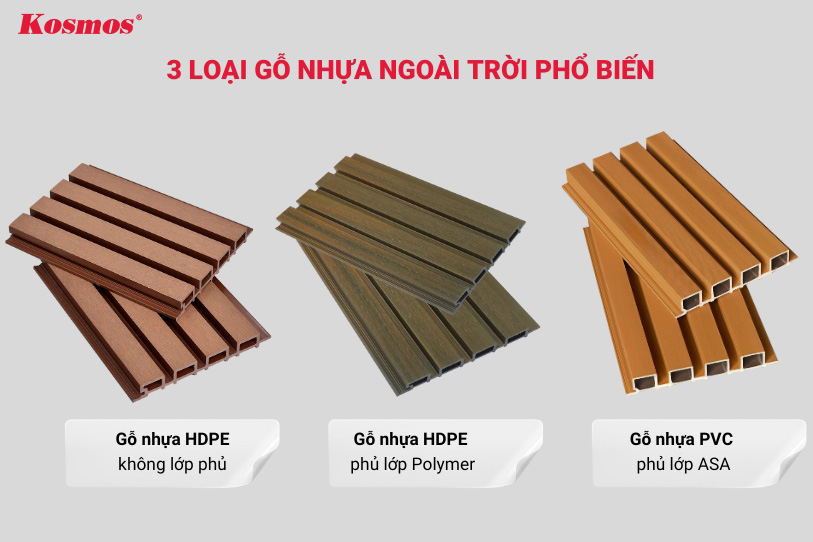

3 types of plastic wood currently popular on the market are:

- HDPE plastic wood without coating.

- Polymer-coated HDPE plastic wood.

- PVC plastic wood coated with ASA layer.

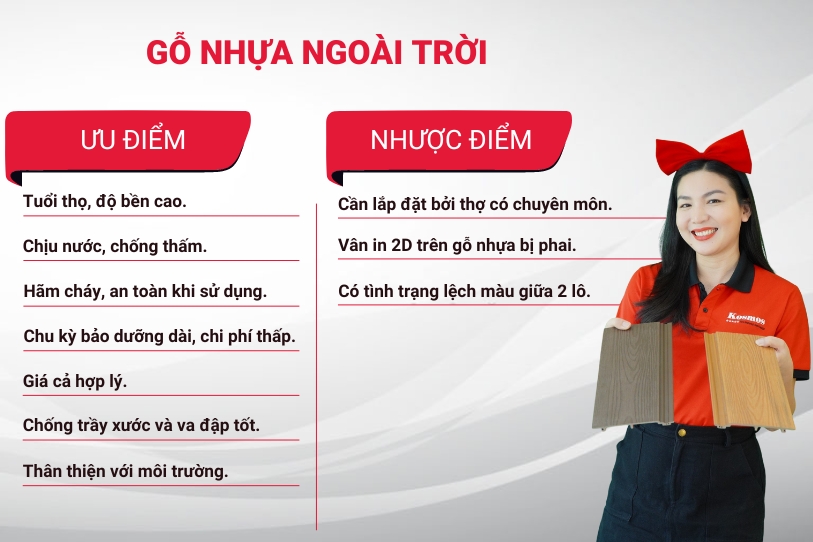

Advantages of outdoor plastic wood are:

- Long life, high durability.

- Water resistant, waterproof.

- Fireproof, safe to use.

- Long maintenance cycle, low cost.

- Good price.

- Good scratch and impact resistance.

- Environmental friendliness.

Disadvantages of wood plastic composite are:

- Cannot be painted or polished to renew the product.

- Needs to be installed by a qualified technician.

- 2D printed patterns on plastic wood fade after long periods of use.

- There is a color difference between 2 different batches.

We can use plastic wood outdoors for flooring, wall cladding, gate cladding, making signs, fences, sunshades, pergola projects, etc.

Outdoor plastic wood construction

3 popular types of plastic wood

There are many different recipes for manufacturing plastic wood and are classified according to factors such as the type of plastic and the coating included. Currently there are 3 popular types of plastic wood:

- HDPE plastic wood without coating.

- Polymer-coated HDPE plastic wood.

- PVC plastic wood coated with ASA layer.

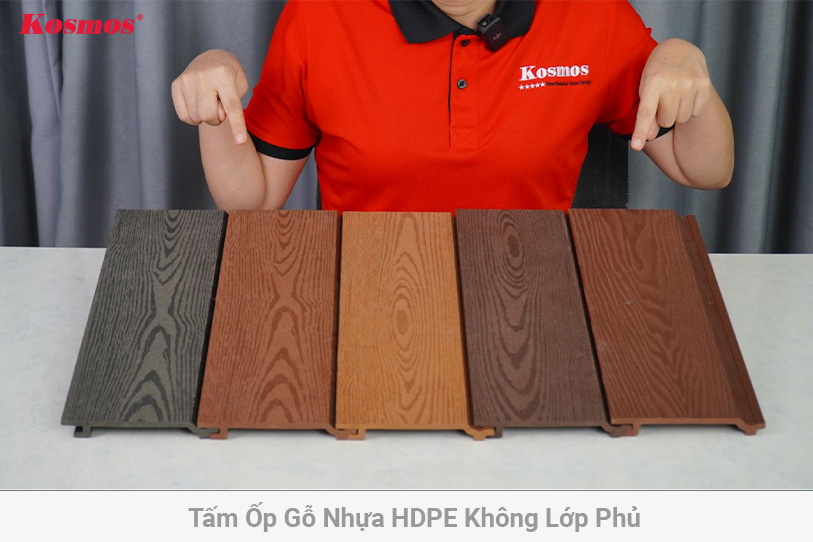

HDPE plastic wood without coating

This is first generation plastic wood, produced in one piece, without separation of layers. There is no coating but the product is still highly scratch resistant, durable and waterproof.

Using HDPE - High Density Polyethylene plastic makes the product have high rigidity (HDPE plastic is stronger than PVC plastic, lower than PP plastic). In particular, HDPE is a plastic line with a high-density molecular structure, so it can withstand impact and stretch better than regular PE plastic. Thanks to the use of this type of plastic, the product resists insects, mold and rot well. In addition, it also helps the product withstand most acids, bases, and natural chemicals.

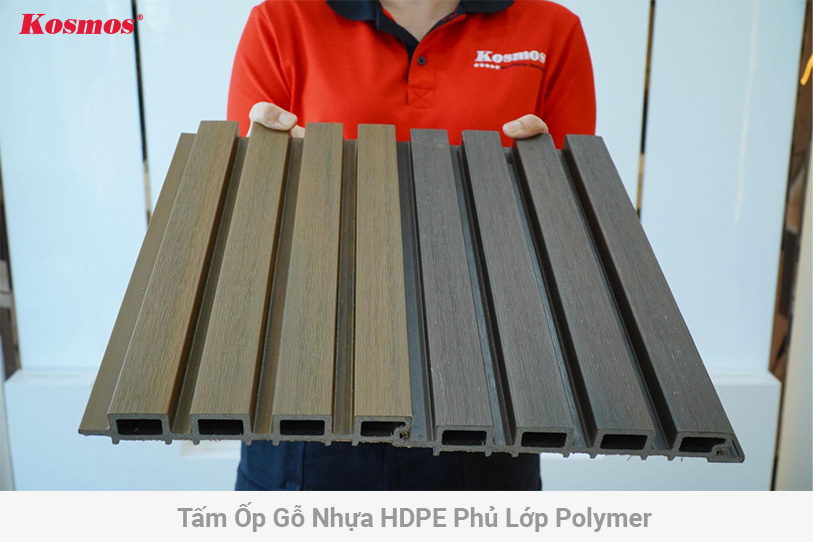

Polymer-coated HDPE plastic wood

This is second generation plastic wood, also known as 2 skin plastic wood. In addition to the core layer made from wood pulp, HDPE plastic and additives, the product is also covered with a comprehensive protective Polymer layer. The product has higher stability than the uncoated type and has a greater variety of colors.

Polymer coating helps protect the product from water, limits fading due to ultraviolet rays and provides high scratch resistance.

PVC plastic wood coated with ASA layer

This is plastic wood made from wood pulp, PVC resin and additives. Because PVC plastic has a lower strength than PE plastic, it is only recommended for use as cladding panels. In addition, to have good weather resistance, the product must be coated with an additional layer of ASA - Acrylonitrile styrene acrylate.

ASA usually has a thickness of 0.2 - 0.3mm to meet quality requirements. Too thin will cause white lines along the grain to appear, too thick will cause the product to warp. This is a material used in the production of cars and roof tiles, so it has excellent UV protection and moisture resistance, keeping the product's color durable.

ASA plastic wood has a smooth surface so it rarely stains and is easy to clean. Above all, the coating also helps the product have more colors.

7 Advantages of outdoor plastic wood

Disadvantages of wood plastic composite

Outdoor plastic wood applications

Outdoor plastic wood is often used to:

- Making outdoor floors.

- Wall and ceiling tiles.

- Make a neoclassical Pergola flower trellis.

- Make fence.

- Make a gate.

- Many other applications (eg: making trash cans, making tables and chairs).

Making outdoor floors

From outdoor floor areas such as swimming pools to locations subject to sun and wind such as balcony floors, terrace floors, etc. Plastic wood is suitable for its durability, ease of construction and high aesthetics.

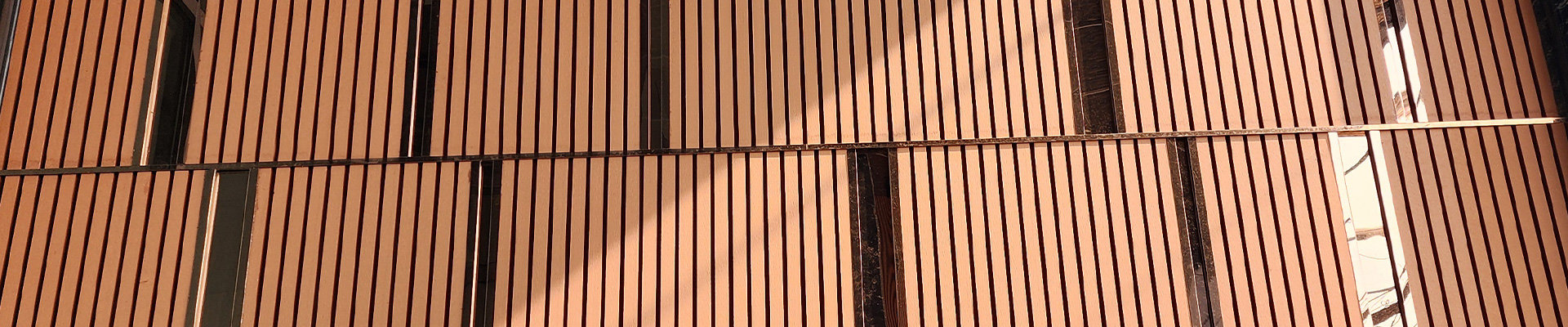

Wall and ceiling tiles

Outdoor wall and ceiling tiles made from plastic wood are beautiful, rustic, and extremely unique and sophisticated. On the other hand, outdoor composite wood plastic has overcome disadvantages such as resisting mold or fading, helping the house always be durable, beautiful and aesthetically pleasing, perfect over time.

Make a neoclassical Pergola flower trellis

Pergola is one of the classic structures that uses plastic wood outdoors. With an open space, surrounded by supporting columns, you can create additional flower racks or small landscape pots.

A neoclassical Pergola flower trellis made from plastic wood will bring a feeling of closeness and warmth. This is also a suitable space for outdoor dining and parties.

Make fence

Fences from plastic wood have been a prominent landscape architectural trend. It promises to be a trend that will be widely applied in the future. Through modern production, plastic wood will help make the fence sustainable over time.

Currently, park fences, terraces, gardens, balconies, etc. all use outdoor plastic wood materials.

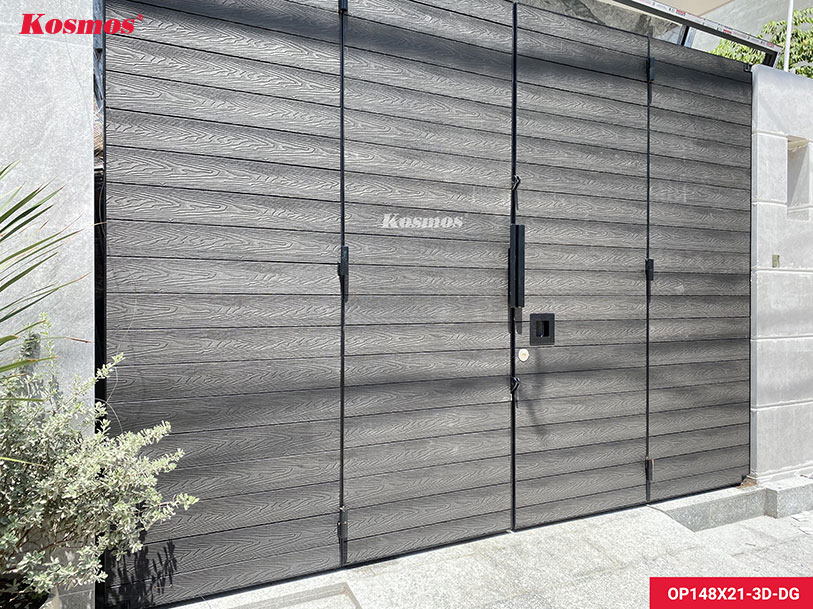

Make a gate

Thanks to the beauty that is close to natural wood, many people use plastic wood to make gates for their homes.

Gates made from composite wood and plastic materials will have many superior properties. Typically, the gate is termite-proof, warp-free, heat-resistant and color-fast over time.

Plastic wood is produced on the basis of modern technology, ensuring the gate will be firm and safe to use. The application of plastic wood as a gate also adorns the house with a natural, modern and luxurious look.

Many other applications

Outdoor plastic wood applications can also be used to make trash cans or outdoor furniture,...

Trash can

Trash cans made from plastic wood will have a long service life, be durable, and look beautiful over time. Therefore, they are trusted and have many meanings in preserving and protecting the environment.

- Furniture

Using outdoor plastic wood to make chairs and tables is highly durable and easy to clean. This is a fairly new material, your house will become perfect, more modern and catch up with new trends.

Frequently asked questions about plastic wood

1. Does outdoor plastic wood have discoloration?

Plastic wood has discoloration.

4 causes of plastic wood color deviation are:

- Due to the color of the input materials.

- Due to the production process Due to visual effects.

- Due to exposure to the natural environment in the early stages.

* When exposed to the outside environment, the product will fade about 5 - 10% in the first 3 months. After that, the color will stabilize, not affecting the quality of the project.

>>> Explain in detail the causes and how to handle discolored plastic wood.

2. Is outdoor plastic wood cheaper than wood?

Outdoor resin can be more expensive than low-grade lumber but cheaper than high-end hardwoods such as: mahogany, cherry, walnut and oak (depending on the specific species).

3. Is wood plastic composite better than wood?

Plastic wood's durability is improved, requires less maintenance and offers more designs than natural wood. However, real wood can provide a more natural feel and aesthetic.

4. How long does outdoor plastic wood last?

Outdoor plastic wood can last 10-25 years or more if installed and cared for properly.

5. Can we paint plastic wood products?

Painting plastic wood products is not recommended as it may affect its performance and appearance.

6. How do you clean plastic wood?

Plastic wood can be cleaned with soap, water and a soft brush. Avoid using harsh chemicals or corrosive detergents.

7. Is wood plastic composite easy to install?

It is not difficult to install plastic wood products. However, Using plastic wood in harsh outdoor areas requires proper attention when installing. Professional assistance from a team of specialized workers will ensure product durability, longevity and performance.

8. Is it possible to use composite wood and plastic indoors?

Plastic wood can be used indoors but is not completely suitable for all product lines. For example: Kosmos plastic wood flooring must be installed on a skeleton frame so it is not recommended for indoor use.

9. Can wood-plastic composite (WPC) be recycled?

Wood-plastic composite (WPC) can be recycled, but it depends on several factors:

- Ingredient: The proportion and type of recycled plastic used in a WPC product directly affects its recyclability. Products with a higher percentage of recycled plastic and fewer additives often have better recycling potential.

* HDPE is an easy-to-recycle plastic, helping to save resources, reduce plastic waste, and contribute to environmental sustainability.

- National Facility: Not all recycling facilities accept WPC due to its synthetic nature. It is important to check with your National recycling program to see if they accept WPC and what specific requirements or limitations they may have.

- Status: Weathered, damaged or heavily painted WPC may not be accepted in recycling programs.

10. What is the difference between plastic wood and wood imitation plastic?

Both are composite materials, but plastic wood is a product that combines wood and plastic, while wood-like plastic only uses plastic and additives, covered with decorative film.

Specific plastic wood like products Kosmos outdoor plastic wood flooring Can withstand harsh outdoor conditions while wood imitation plastic cannot be exposed to the sun for too long.

11. How much does outdoor plastic wood cost?

On the market, the price of plastic wood ranges from 143.000 - 510.000 VND/meter long..

Note: Prices for outdoor plastic wood are given according to each product line (outdoor plastic wood flooring / indoor), type of plastic wood, brand, size and accompanying costs such as: installation costs, accessories, labor, transportation (if any).

General, Outdoor plastic wood is a product that can replace natural wood to decorate exterior spaces, is not affected by termites and reduces maintenance costs. To learn more about the product or learn more about the policy of becoming a plastic wood distributor, please leave your information below.

You will receive quotation advice and the latest construction samples of outdoor plastic wood, when entering the information below.

Kim Hoa is an expert in interior and exterior decorative materials at Kosmos Vietnam. She has professional knowledge of interior design and loves finding creative ways to optimize space with simple construction decoration materials such as wood, stone, bamboo, brick and plastic.

Kim Hoa Regularly participate in seminars and exhibitions on interior decoration materials to update the latest trends, as well as to learn more about interior decoration materials. Meet interior and exterior designers, architects, and material experts to continuously learn. She also actively shares her knowledge and experience on social media channels such as Facebook, YouTube, Tiktok... with more than 100 thousand followers.

Mission of Kim Hoa not merely providing information, but also ensuring that All information posted is quality, has in-depth investment and is most useful to viewers.