Laminate flooring

What is laminate flooring?

Laminate flooring is one of the living space decoration materials favored by many users today. This flooring material stands out with its high aesthetics, simulating the natural and rustic beauty of wood.

Besides, this type of wooden floor goes through a modern production process so it possesses many superior features. Typically, it has good water resistance, moisture resistance, termite resistance and long-lasting strength and heat resistance. The product promises to bring you the best experience.

Newsletter for laminate flooring

6 Ways to choose the most suitable laminate flooring

Guide to choosing the thickness of laminate flooring

Laminate flooring: Structure, advantages and disadvantages, classification, price quote

Laminate Flooring is a flooring material for houses, townhouses, villas, and apartments that has been loved and commonly used for many years. With a sturdy 4-layer structure and smart locking mechanism, this product brings many outstanding advantages such as good strength, anti-fouling, safe for health, high durability, quick construction, good design. diversity.

However, laminate flooring also has some limitations such as poor water resistance and susceptibility to termites

Currently, there are many ways to classify laminate floors such as:

- Based on thickness

- Based on features and price

- Based on wooden core.

The price of laminate flooring ranges from 210.000 to 650.000 VND/mXNUMX.2 depending on origin, product origin, production technology,...

To better understand this Laminate wood floor, see the detailed article below.

What is laminate flooring?

Laminate flooring is a flooring material that replaces natural wood floors. They are produced by pressing and compressing wood powder, mixing with a number of accompanying additives, thereby creating floor panels with durable HDF wood core.

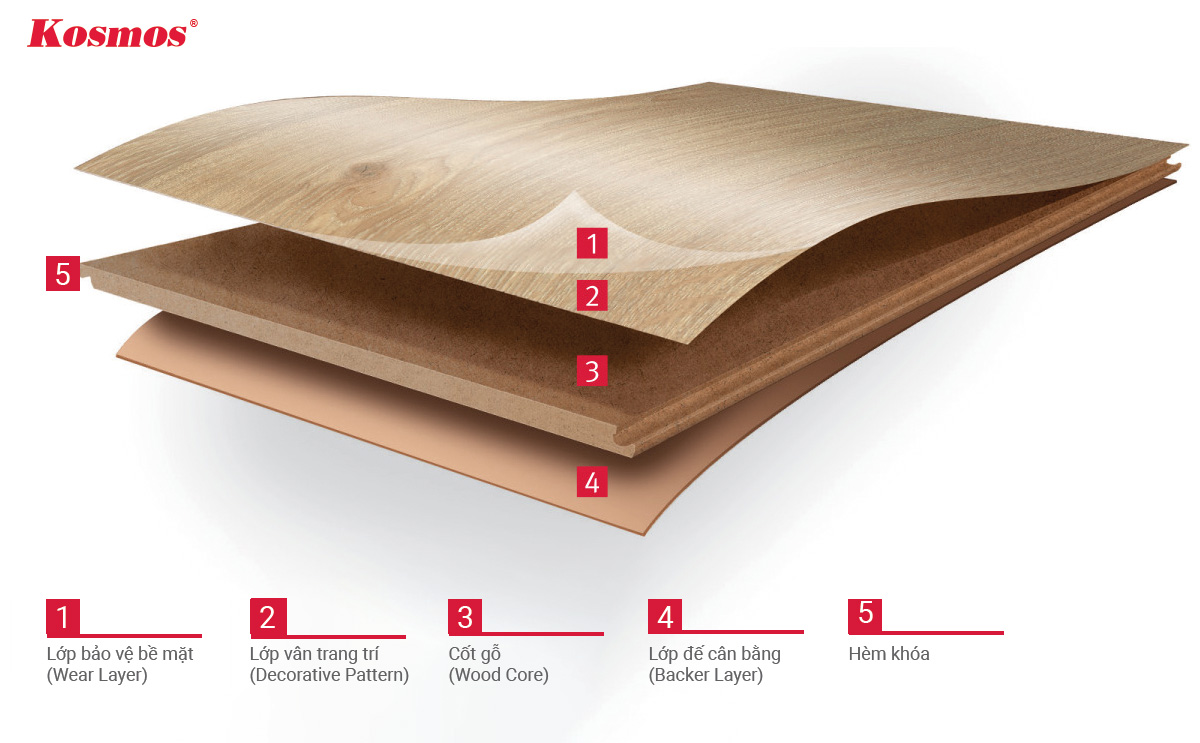

Structure of industrial wood floor

The general structure of laminate flooring includes 4 layers and a smart lock system. The structural layers are tightly bonded together using high-pressure compression technology, specifically as follows:

- Surface protection layer: Made of Melamine or Acrylic plastic with a thickness of approx 0.2 - 0.3mm. The main function of the surface protection layer is to improve scratch resistance (the index showing scratch resistance is AC), prevent fading, limit stains and waterproof the floorboards.

- Decorative layer: It is a layer of wood grain printed paper about approx 0.08 mm create diverse designs and colors.

- Wood core layer: 8 - 12mm thick and composed of wood pulp 80 - 85%, the binder accounts for 10 - 15% , and 5 - 10% The rest are accompanying additives. The wood produced is only harvested from licensed forests and is formed after the process of boiling - drying - grinding wood. Depending on the production technology, the wood core has unique features of water resistance, termite resistance, load resistance, anti-warping, etc.

- Balanced sole layer: Mainly composed of approx. thick synthetic resin 0.2 - 0.5mm helps protect the floor from below, prevents moisture from penetrating the foundation and reduces noise when moving.

- Lock button: Connect the floorboards with negative - positive joints, improving stability and convenience during installation. Each brand will have a different design of the lock.

Advantages

Laminate flooring is not only highly aesthetic but also has 6 outstanding advantages as follows:

- Bearing good

- Anti-fouling

- Health safety

- Durable

- Fast construction

- Various models

Bearing good

IC (Impact Resistance) is an index showing the bearing capacity of Laminate wood floors with units of kg/m2.2. Currently, there are two popular IC indices: IC2 and IC1. The bearing capacity of laminate flooring falls into the IC2 index (withstands force of about 2N).

Anti-fouling

Manufactured using advanced technology, the anti-friction and anti-UV outer surface protection layer also helps stains not stick to the floor for a long time and is easy to clean.

Health safety

Circular 04/2023/TT-BXD promulgating National Technical Regulations on construction materials products and goods according to QCVN 16:2023/BXD regulating Formaldehyde concentration (a gaseous organic compound with an odor). harmful effects on human health) in laminate flooring must reach E1 index. Specifically, the Formaldehyde emission content in the flooring must be ≤ 0,124mg/m³ or not >9 mg/100g. With the E1 index, laminate floors are absolutely safe for users.

Durable

Laminate flooring is produced with the main ingredients being wood powder, additives, etc., undergoing a high compression process. Thanks to that, the product has high durability and an average lifespan of from 15 - 20 year, even longer lasting if users use and preserve it properly.

Fast construction

Laminate flooring is designed with smart locking seams, a pre-designed system of negative and positive seams to help the floor boards bond tightly together. This factor makes installation easier, saves time and construction costs while still ensuring high accuracy.

Various models

Laminate flooring today has many designs for users to choose from, from bright neutral tones to warm tones. The wood grain patterns on the surface of the floorboards are also very diverse, from simple to sophisticated and sophisticated. Besides, laminate flooring is also produced with many designs from large slabs, small slabs to herringbone floors,... users have many options for their projects.

Disadvantages

Besides the above outstanding advantages, laminate flooring still has some limitations such as not being suitable for use in wet areas and being susceptible to termites.

Not suitable for wet places

99% of laminate floors are not water resistant, except for some types that are guaranteed by the manufacturer with a flood warranty. Because of that, when wooden floors are exposed to areas with high humidity for a long time, the wooden floors can blister, warp, and become damaged. If the living space is often wet or the weather conditions are often humid, we should prioritize using wooden floors with a guaranteed flood warranty such as Egger Aqua, which is recognized by NALFA to block surface water. for 72 hours and is the only laminate flooring line that commits to a waterproof warranty up to for 1000 hours.

Vulnerable to termites

Although termites are treated during the production process, not all laminate floors have good termite resistance. Some products made from synthetic wood used in environments with high humidity will be favorable for bacteria, mold, and termites to develop and attack through gaps in the wood core.

Classification of laminate flooring

We can rely on thickness, features, price, and wood core to classify laminate floors.

Based on thickness

On the market today, wooden floors come in many different thicknesses including: 7mm, 8mm, 10mm, 12mm, 14mm, 15mm,... the most popular are 8mm and 12mm.

- 8mm wooden floor: The flooring meets the necessary standards, used for residential spaces, offices, etc. with relatively high traffic density.

- 12mm wooden floor: It is the perfect choice for areas with high traffic density such as shopping centers, schools, etc. 12mm thickness will help the floorboard have good bearing capacity, effective impact resistance, and improved durability. construction.

Based on features and price

Based on features and price, laminate flooring is divided into two main types:

- High quality wooden floors: These are wooden floors imported from Germany, Malaysia, Belgium, Türkiye with prices ranging from 450.000 to 950.000 VND/mXNUMX.2 With many features such as water resistance and termite resistance.

- Cheap wooden floors: These are wooden flooring lines from Vietnam and China with prices ranging from 210.000 - 360.000 VND/mXNUMX.2.

Based on wooden core

Based on the type of wood core, laminate flooring will include the following lines:

- Regular core wood floors: Made from recycled wood, going through a high compression process, has a lower price than green core, black core,...

- Moisture-proof and water-resistant reinforced wood floors: This is a line of wood flooring with HDF core that is water-resistant and moisture-proof, suitable for areas with high humidity.

Latest price quote for laminate flooring

The price of laminate flooring will have a certain difference due to origin, brand and size. Below is a detailed price list.

PRICE LIST OF INDUSTRIAL WOOD FLOOR | |

| Origin | Price (VND/m2) |

| Vietnam | 270.000 – 360.000 |

| Malaysia | 450.000 – 600.000 |

| German | 650.000 - 950.000 |

| Thailand | 270.000 – 350.000 |

| Chinese | 210.000 – 240.000 |

Note: The above price list was last updated on April 4. Depending on each distributor, shipping costs, after-sales policies, etc., there will be more or less price differences.

Where to buy quality laminate flooring?

Kosmos is one of the large-scale industrial wood flooring distribution warehouses in Vietnam. With more experience in the industry is 10 years Kosmos is a reputable business for you to refer to about laminate flooring materials. With a team of experienced staff, Kosmos is also always willing to provide consulting support and answer customers' questions.

Related question

What is the difference between laminate flooring and natural wood flooring?

Laminate flooring is produced from pressed wood pulp and additives, while natural wood flooring is a direct product from 100% natural wood.

| Comparative Criteria | Laminate flooring | Natural wooden floor |

| Price | Cheaper | More expensive |

| Reliability | Lower | Higher |

| Water resistance | Ke M | Ke M |

| Anti-termite ability | Ke M | Ke M |

| Material | Wood pulp pressed with high pressure | Solid natural wood |

| Construction time | Fast | Late gratitude |

Is laminate flooring waterproof?

Laminate floors are not water resistant except for some types that are guaranteed by the manufacturer with a flood warranty such as:

- Egger Aqua wooden floors are committed to a waterproof warranty for 1.000 hours

- Robina Aqua wooden floors are committed to a waterproof warranty 10 consecutive days

How to clean industrial wood floors?

Cleaning wooden floors properly will contribute to improving the durability of the floor, we can apply the following steps:

- Sweep or vacuum the floors

- Wipe the floor with a damp cloth or specialized solution

- Use a soft towel to dry the floor.

Is laminate flooring harmful to health?

Circular 04/2023/TT-BXD promulgating National Technical Regulations on construction materials products and goods according to QCVN 16:2023/BXD requires Formaldehyde concentration to meet E1 standard not to harm human health Can be used even by young children.

Does laminate flooring affect the floor?

Laminate flooring does not affect the floor.

>>> Should you install wooden floors on old ceramic tile floors?

Which wall color is suitable for laminate flooring?

Choose an industrial wood floor color that matches the wall color will contribute to increasing the aesthetics and creating harmony for the space.

- With light walls we can combine with light wooden floors to create a bright, open feeling or apply dark wooden floors to create a highlight and make the space more cozy.

- The walls of the house are dark, to balance the color of the space, we should prioritize choosing light-colored wooden floors. If you want the space to become mysterious and luxurious, you can also use dark wooden floors similar to the wall color.

Things to note when choosing to buy laminate flooring?

To choose to buy quality laminate flooring, suitable for the project, we need to note the following factors:

- Determine usage needs

- Wood core quality

- Floorboard thickness

- Surface effect

- Wood floor color

- Reasonable price

- Reputable supplier,…

>>> Mistakes when choosing laminate flooring.

Does laminate flooring need to be polished?

Laminate floors do not need to be polished like natural wood floors. Polishing can affect the quality of the floor covering.

Can I use foam when constructing wooden floors?

During the construction of wooden floors, do NOT overlap foam. Stacking will cause the floor to warp and make noise during use.

>>> Instructions on how to properly construct laminate flooring:

What standards does the wooden floor installation environment need to meet?

To protect wooden floors, construction units recommend:

- The installation area must be well ventilated

- Construction temperature must be above 18 degrees Celsius

- The floor surface temperature must be above 15 degrees Celsius

- Do not expose the floor to heat sources above 50 degrees Celsius

- Make sure the humidity in the air is between 40% and 70%.

The above article has provided detailed information about laminate flooring, if you have any questions, please contact us via phone (+84) 903 093 221 for fastest support.

Kim Hoa is an expert in interior and exterior decorative materials at Kosmos Vietnam. She has professional knowledge of interior design and loves finding creative ways to optimize space with simple construction decoration materials such as wood, stone, bamboo, brick and plastic.

Kim Hoa Regularly participate in seminars and exhibitions on interior decoration materials to update the latest trends, as well as to learn more about interior decoration materials. Meet interior and exterior designers, architects, and material experts to continuously learn. She also actively shares her knowledge and experience on social media channels such as Facebook, YouTube, Tiktok... with more than 100 thousand followers.

Mission of Kim Hoa not merely providing information, but also ensuring that All information posted is quality, has in-depth investment and is most useful to viewers.