Plastic Panels

WHAT IS PLASTIC SHEET?

Plastic panels are indoor wall and ceiling panels made of plastics (eg PVC plastic, PS plastic, Composite plastic). They are lightweight and water resistant so they are easy to apply and clean. The lifespan of plastic wall panels can be up to 20 years if used and constructed properly.

Plastic wall panels can imitate wood, imitation stone, imitation cement, etc. thanks to the decorative film layer. However, this film can discolor due to UV rays, so exposure to direct sunlight should be avoided.

"Plastic cladding that simulates wood and stone has become increasingly popular in recent years due to its affordable price, high durability and ease of maintenance. These panels provide a realistic and aesthetically pleasing alternative to traditional materials, making them a desirable choice for both residential and commercial applications..” – According to Dr. Sarah Williams, Professor of Interior Design at the University of California, Berkeley.

Get product quote

Please select a retail or agency quote below

Plastic cladding newsletter

What is a Kosmos plate? Classification and Application

Instructions on how to properly clean fake wood wall panels

What is plastic cladding? advantages and disadvantages, classification, applications, quotes

Plastic cladding is a type of interior decoration material commonly used for wall and ceiling cladding. They are made from PVC/PS or composite plastic, are light in weight, easy to construct and clean. If constructed and used properly, the lifespan of plastic panels can be up to 20 years.

With decorative film that can imitate wood, imitation stone, etc., plastic wall/ceiling panels easily bring a luxurious, modern beauty to the space. Especially the product is 100% water-resistant and termite-proof.

10 advantages of plastic panels that we cannot ignore are:

- Absolutely waterproof

- Anti-termite and insect

- Easy cleaning

- Fast construction

- Durable

- Rich designs

- Variety of sizes

- Anti-fire spread

- Health safety

- Reasonable price

Here are 3 disadvantages of plastic panels that users need to consider:

- Faded by UV rays (sun rays)

- The bearing capacity is lower than brick, stone, and wood

- Easily scratched when in contact with sharp objects

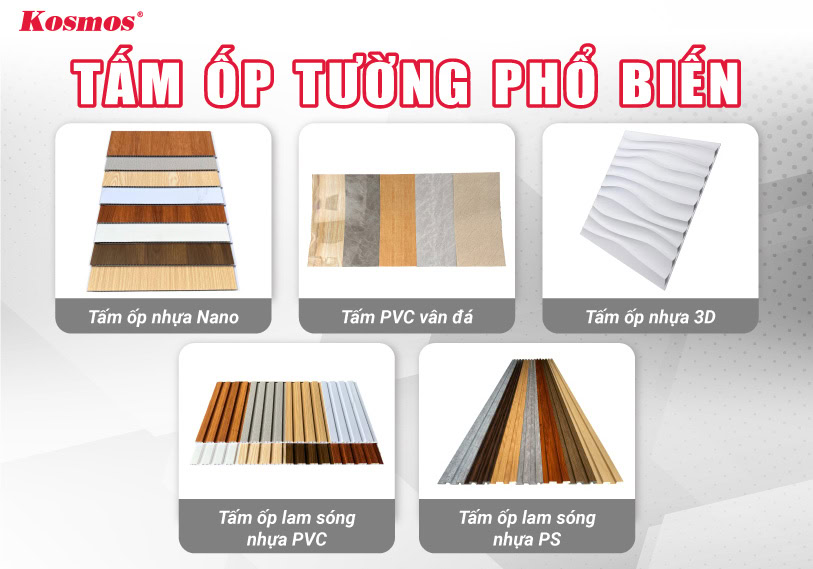

When buying, you can consider 5 popular types of plastic wall panels on the market:

- Nano plastic panels

- Stone grain PVC sheet

- PVC fluted panel

- PS plastic fluted panel

- 3D plastic panels

According to Dr. Sarah Williams, Professor of Interior Design at the University of California, Berkeley: “Plastic cladding that simulates wood and stone has become increasingly popular in recent years due to its affordability, durability and ease of maintenance. maintain. These panels provide a realistic and aesthetically pleasing alternative to traditional materials, making them a desirable choice for both residential and commercial applications.”

Therefore, wood grain and stone grain are the two most popular plastic cladding models, followed by white plastic cladding panels.

We can use plastic panels to:

- Walling

- Ceiling tiles

- TV wall panel

- Lamri cover

The price of plastic wall and ceiling decorative panels is in the range of 240.000 - 691.000 VND/m²

Why are plastic wall panels popular?

Plastic wall panels are popular because of the following advantages:

- Absolutely waterproof.

- Anti termite and insect.

- Easy cleaning

- Fast construction

- Durable

- Rich designs

- Variety of sizes

- Anti-fire spread

- Health safety

- Reasonable price

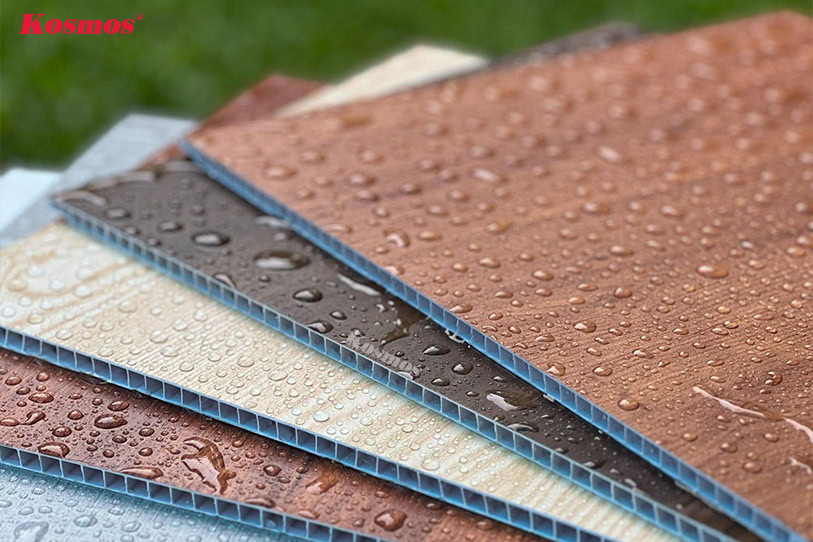

Absolutely waterproof

The most outstanding advantage when using decorative plastic wall panels is their absolute waterproof ability. This helps protect your walls from mold, peeling, and mold, especially in areas with humid seasons.

Anti-termite and insect

Panels are made from PVC/PS or composite plastic, which is effective against termites and insects. This helps protect your walls from damage, saving on maintenance costs.

Easy cleaning

The surface of the plastic panel is smooth, dust-free, and easy to clean with a damp cloth or soapy water.

Note: We must not use concentrated detergents or hard brushes to clean.

Fast construction

Plastic wall panels are light in weight, easy to construct, quick to install, saving time and costs.

Durable

Plastic wall panels are highly durable, with a lifespan of up to 20 years, even longer if used and maintained properly. The product is not easily warped or deformed when exposed to high temperatures.

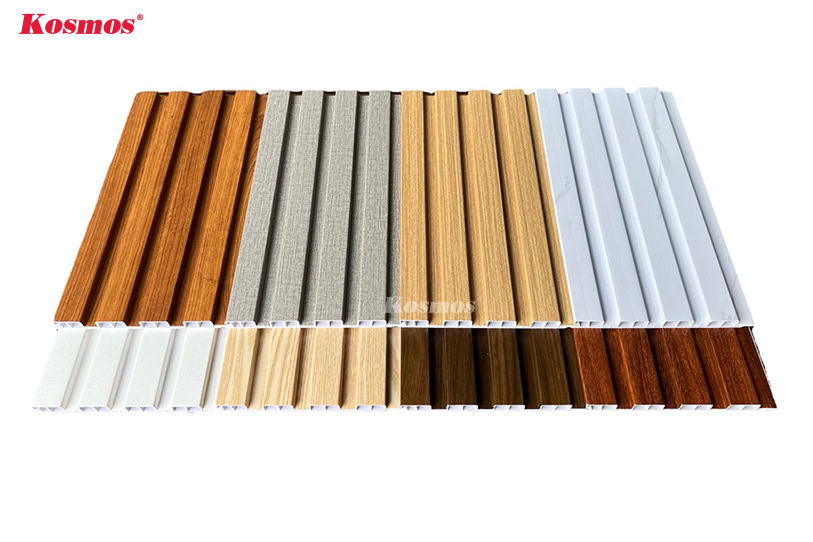

Rich designs

The production process of plastic wall panels is relatively simple, allowing the creation of many different designs at low cost. Manufacturers meet market demand by diversifying the colors and patterns of plastic wall panels from imitation wood, imitation stone, imitation cement to monochrome panels.

Diverse shapes and sizes

Plastic panels come in many different shapes and sizes, including:

- Flat panels: Nano panels 8 - 9mm thick and stone-grained PVC panels 2.8 - 3mm thick.

- Fluted panel panels with different designs of high wave, low wave, single wave, double wave, thickness ranging from 15 - 30mm.

Anti-fire spread

Wood-imitation plastic panels are more resistant to fire spread than natural wood. When the temperature increases, the plastic sheet will melt, slowing down the fire and preventing the spread of fire.

Health safety

Plastic panels do not affect human health if they are produced from virgin plastic and do not contain impurities and harmful toxic gases.

Wall panels made of virgin PVC are easy to recognize because:

- Bright white virgin PVC plastic core.

- Phone LED lights can penetrate through the back panel.

Reasonable price

Natural wood wall panels cost from 920.000 - 2.150.000 VND/m² (depending on the type of wood). Marble wall tiles cost from 1.150.000 - 6.000.000 VND/m². Meanwhile, whether it is imitation oak or cedar wood, or even imitation marble, plastic wall panels only cost around 240.000 - 691.000 VND/m²

What are the disadvantages of plastic cladding?

Disadvantages of plastic cladding include:

- Faded by UV rays (sun rays). You should not install the product in outdoor areas such as porches or balconies.

- The bearing capacity of plastic panels is lower than that of bricks, stone, and wood. Therefore, we should not apply too much force to the edges of the panel.

- Easily scratched when in contact with sharp objects. We should only clean the product with a soft cloth, not a brush.

5 popular types of indoor plastic wall/ceiling panels

5 popular types of indoor plastic wall/ceiling panels are:

- Nano plastic panels

- Stone grain PVC sheet

- PVC fluted panel

- PS plastic fluted panel

- 3D plastic panels

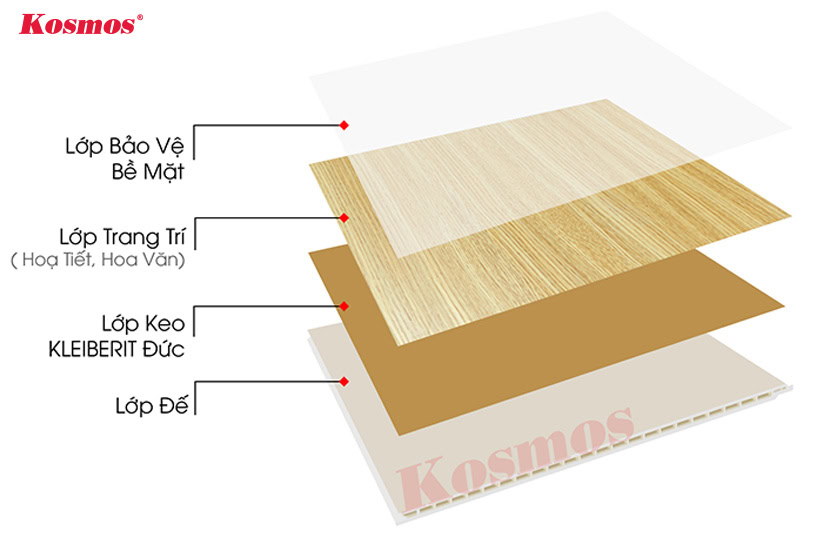

Nano plastic panels

Nano plastic panels (Nano panels) are flat panels made from PVC (Polyvinyl Chloride), depending on the type, there will be additional stone powder ingredients. The product has a thickness of 8 - 9mm with a base with hollow holes to help absorb sound. We will install this product with glue and stainless steel, assembling the panels through locking joints. Most products are designed to imitate wood, however there are still many imitation cement or monochrome stone models for you to choose from.

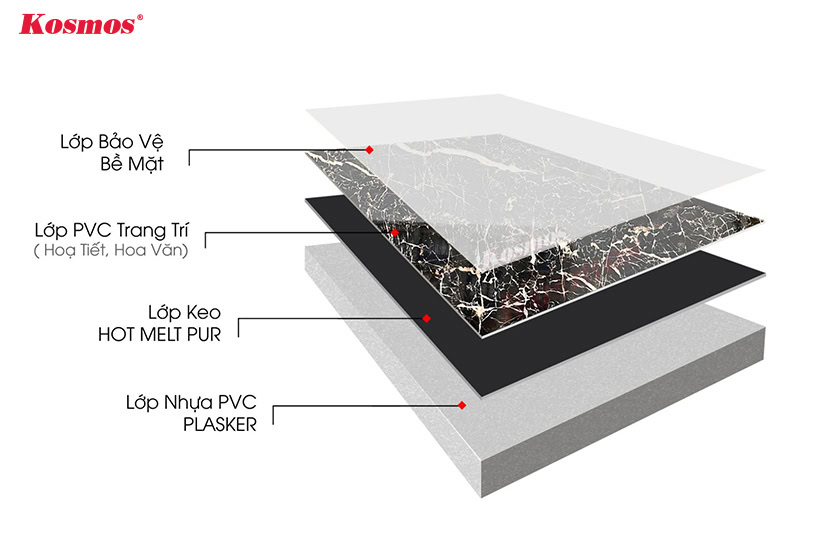

Stone grain PVC sheet

Stone-grained PVC panels (imitation stone plastic panels) are PVC panels mixed with stone powder, about 2.8 - 3mm thin. It has a flat shape with a glossy surface and realistic imitation stone texture. The product does not have a lock, we just need to install the panels next to each other with glue. Thanks to its light weight and flexibility, we can easily install panels at curved corners.

Stone-grained PVC panels are the most effective alternative to natural stone for interior wall cladding today, bringing luxurious beauty to the space at a reasonable price.

PVC fluted panel

PVC fluted panel is a plastic panel with a wavy design, the base is bright white with a decorative film layer on the surface. The product is made of 100% PVC or PVC mixed with stone powder (SPC - Stone Plastic Composite). We will install them similarly to Nano panels, using glue and stainless steel, assembling each panel together through a lock.

Fluted plastic panels are very popular to create highlights in the home, often used in combination with Nano panels and stone-grained PVC panels.

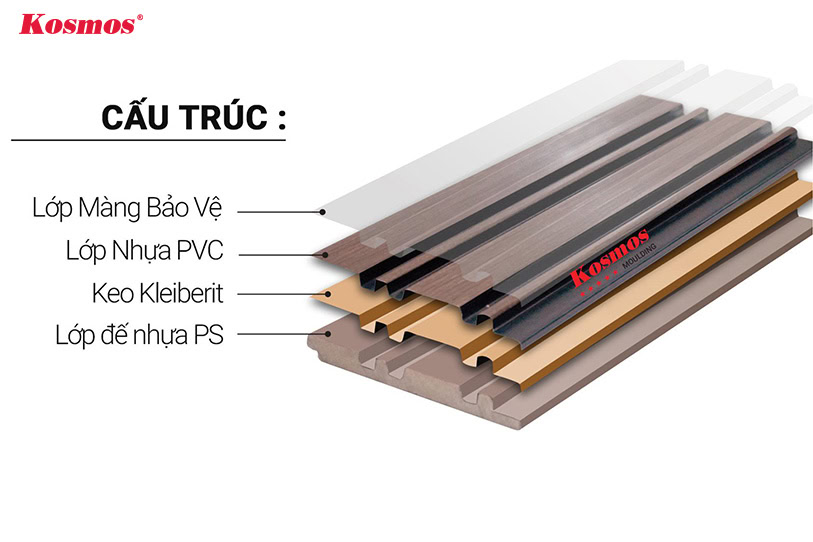

PS plastic fluted panel

Fluted panel PS (Korean fluted panel) is a plastic panel with a wavy design, the base is dark gray with a decorative film layer on the surface. The product is made of PS plastic so it is light in weight and the color is quite eye-catching. We will install them with glue and nails into the recesses of the panel. Installing negative seams into positive seams will hide nail marks, creating a large wall surface without exposed joints.

Korean fluted panel has activated carbon extract to effectively deodorize. Besides, the product is applied high technology, designed in a unique Korean style, catching up with all interior decoration trends.

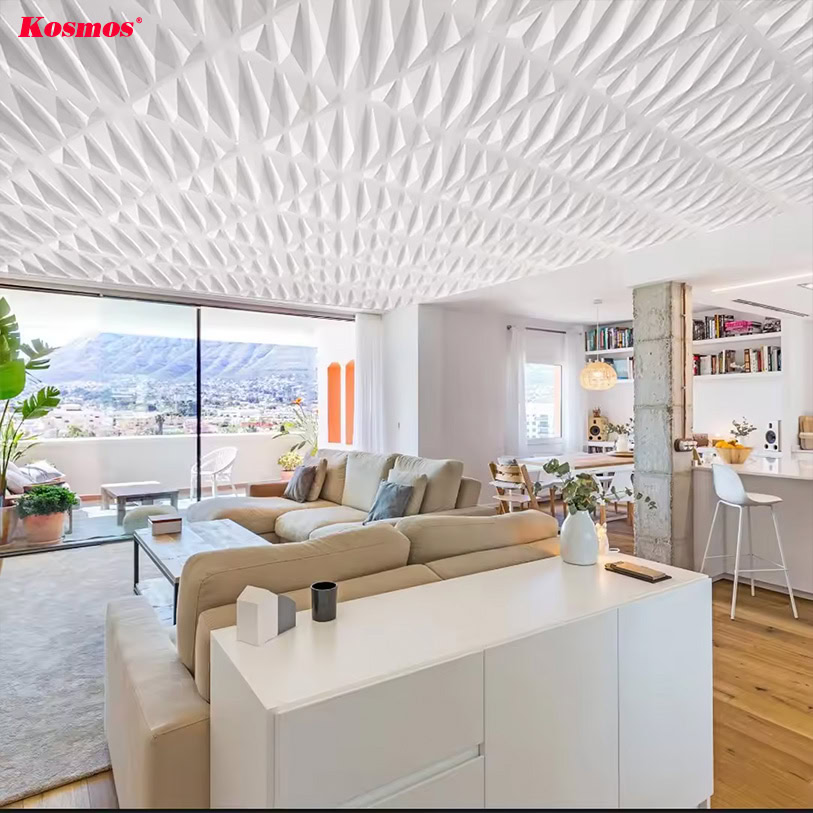

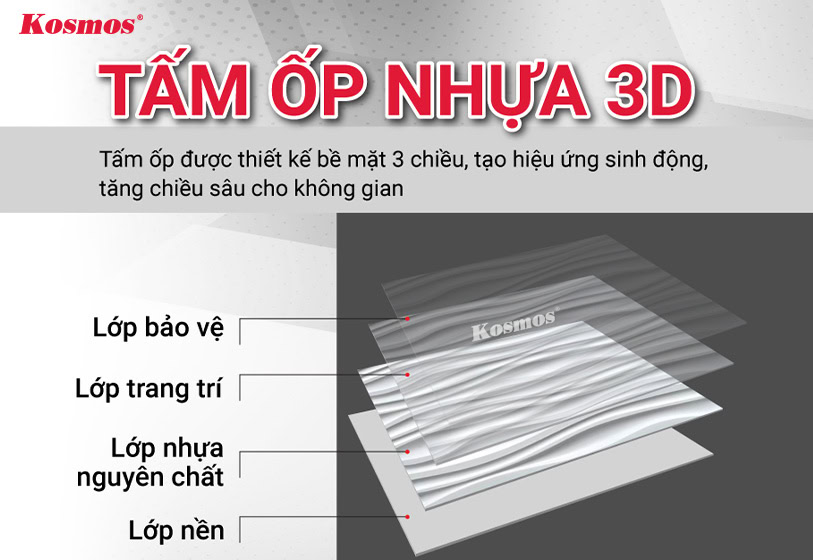

3D plastic panels

3D plastic panels are PVC plastic panels designed to create a 3D effect (3 Dimension - 3 dimensions) for walls/ceilings. The special shape and structure of the panels help create depth for the space, easily creating impressive highlights for guests visiting your home. We often see products in plain white, which can be painted to color as desired. There are also some units that provide pre-colored panels using color printing technology, the color is even and there is no worry of peeling off like manual painting.

3 popular decorative plastic panel models

3 popular decorative plastic panel models are:

- Wood imitation plastic panels

- Imitation stone plastic panels

- White plastic wall panels

Wood imitation plastic panels

Wood-imitation plastic panels are the perfect choice for those who love the natural, luxurious and cozy beauty of wood. With diverse film colors and realistic wood grain, plastic panels bring intimacy and warmth to the space without worrying about termites, mold, or expansion.

Imitation stone plastic panels

Imitation stone plastic panels are the ideal choice for those who want to own a modern, luxurious and sophisticated space. With a film layer with realistic stone patterns, plastic panels help save a lot of costs while still ensuring the aesthetics of the living space.

White plastic wall panels

White plastic wall panels are the ideal choice for those who love simple, gentle and sophisticated style. White brings a spacious, airy and clean feeling to the space.

What is the application of plastic panels in interior decoration?

Plastic panels are often used for wall cladding, ceiling cladding, TV wall cladding, and lamri cladding in interior spaces. Not only does it protect walls/ceilings/siding from mold and peeling, but the panels also increase aesthetics and are easy to clean.

Plastic wall panels

Ceiling plastic panels

Plastic panels for TV walls

Lamri plastic panels

Latest price quote for plastic wall panels

Type of plastic panel | Reference price |

| Corrugated PVC plastic panels | 930.000 – 1.010.000 VND/m² |

| PVC plastic corrugated iron + stone powder | 864.000 – 917.000 VND/m² |

| PVC Nano panel + stone powder | 721.000 – 936.000 VND/m² |

| PS plastic corrugated lamella | ~1.040.000 VND/m² |

| PVC Nano panels | 771.000 – 886.000 VND/m² |

| Stone grain PVC sheet | 675.000 – 711.000 VND/m² |

| 3D plastic panels | ~200.000 – 260.000 VND/m² |

Note:

- The above price list was updated in April 4

- The above price is the complete price including materials + installation labor costs

Other questions about plastic cladding

What is the difference between imitation wood plastic panels and plastic wood panels?

| Wood imitation plastic | Plastic wood | |

| Structure | Mainly made from plastic (PVC/PS). | Made from a mixture of plastic (PVC/PE/HDPE) and wood pulp |

| Durability and bearing capacity | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Scratch resistance | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Resistant to fading | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Price | Short | High |

| Application | Interior materials | Exterior |

Imitation wood and plastic wood both give the house the rustic beauty of natural wood.

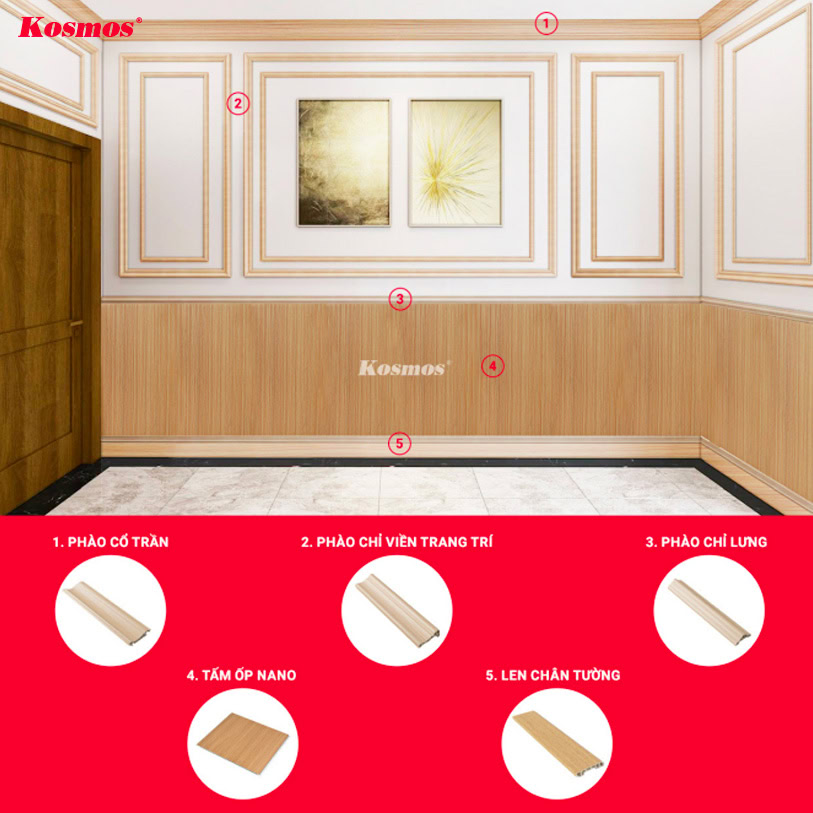

What do plastic wall panel accessories include?

- Ceiling molding: Covers the intersection between the wall and ceiling.

- Wall back molding: Decorate the back wall.

- Decorative cornice: Creates a decorative border for the door frame.

- Concealed corner molding: Decorate the corner inside the wall.

- End clip: Covers the end of the panel.

- V brace: Square corner decoration.

- Brace H: Connects two panels together.

- Skirting: Covers the intersection between the wall and floor.

How much does it cost to construct plastic TV wall panels?

The construction price of plastic panels for TV walls is around 10.000.000 VND.

Construction price depends on the scale of the project, labor costs, quantity of materials and accessories. Therefore, we must estimate the price on a specific project like the following video:

- Project area: 12m²

- Labor cost: 250.000 VND/m².

- Shipping cost: 300.000 - 400.000 VND.

- Material cost: ~6.790.000 VND/12m².

Supplies include:

- 8m² fluted PVC panel.

- 6m² stone grain PVC panels.

- The TV wall is designed in a box style, so it requires 30m of u-shaped aluminum bars as the skeleton.

- 3 V-shaped plastic splints.

- 8m aluminum bar.

How much does it cost to construct a faux wood plastic ceiling?

Construction price of faux wood plastic ceiling is about 700.000 - 1.350.000 VND/m².

| Mounting type | Reference price |

| Drop ceiling | 700.000 – 950.000 VND/m² |

| Level 1 recoil ceiling | 900.000 – 1.150.000 VND/m² |

| Level 2 recoil ceiling | 1.000.000 – 1.350.000 VND/m² |

Note: The price of 1m² of this faux wood plastic ceiling is not fixed and is for reference only. We will refer to this price as the market reference in April 04.

Is it difficult to construct PS plastic fluted panels?

Construction of PS plastic fluted panel is not difficult, including 7 steps:

- Step 1: Prepare tools and supplies.

- B2: Renovate the wall surface to be flat, dry or install a skeleton.

- B3: Measure and cut PS plastic fluted panel.

- B4: Apply glue to the back of the panel or frame (if any)

- B5: Shoot nails into the recess of the panel.

- Step 6: Install the next panel through the lock.

- B7: Install accessories/Brace for fluted PS plastic panel.

Is it difficult to construct stone-grained PVC wall panels?

Construction of stone-grained PVC wall panels is not difficult, including 6 steps:

- Step 1: Prepare tools and supplies.

- B2: Surface treatment of stone-grained PVC panels.

- B3: Measure and cut stone-grained PVC panels to the required size.

- Step 4: Apply specialized glue & apply double-sided glue to the back of the panel.

- B5: Fix the stone-textured PVC panel to the wall.

- B6: Install accessories/Brace for stone-grained PVC panels.

Is it difficult to construct Nano plastic wall panels?

Construction of Nano plastic wall panels is not difficult, including 7 steps:

- Step 1: Prepare tools and supplies.

- B2: Renovate the construction wall surface to make it flat.

- B3: Measure and cut Nano panels.

- Step 4: Apply glue to the back of the Nano panel.

- Step 5: Fix the Nano panel on the wall with stainless steel glue.

- Step 6: Install the remaining Nano panel through the lock.

- B7: Install accessories/Brackets for Nano panels.

Note: Panels can be installed on the frame if needed. When installing, we will apply glue to the frame, the distance between the bones should not exceed 500mm.

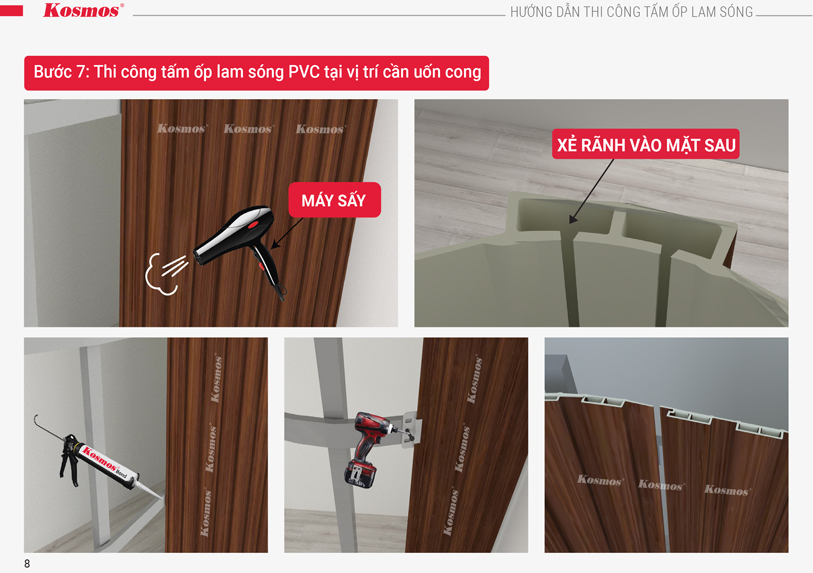

How to install fluted PVC panel at curved corners?

Installation of fluted PVC panel at curved corner include:

- Step 1: Heat the panel.

- B2: Cut grooves on the back of the panel.

- Step 3: Apply glue to the panel or frame (if any).

- Step 4: Fix the plate with screws and stainless steel screws.

- Step 5: Install the next plate through the lock.

Can plastic panels be installed in the toilet?

Because plastic panels are installed with glue, we cannot install the entire bathroom wall. Instead, it should only be installed in a high position to avoid long-term water immersion and damage to the product.

What is the size of the plastic wall panel?

Dimensions of Nano plastic wall panels (width x thickness x length) |

|

Dimensions of stone-grained PVC panels |

|

Size of fluted plastic wall panel | ||

| Fluted panel type | Current | the size (width x thickness x length) |

| Corrugated PVC plastic panels | Lam 3 low wave | 200 15 x x 3000mm |

| Lam 4 low wave | 150 9 x x 3000mm | |

| Lam 4 high waves | 200 25 x x 3000mm | |

| PVC plastic corrugated iron + stone powder | Lam 3 low wave | 198 15 x x 3000mm |

| Lam 3 high waves | 200 30 x x 3000mm | |

| Lam 4 low wave | 152 9 x x 3000mm | |

| PS plastic corrugated lamellas (Korean corrugated lamellas) | Lam 3 waves | 122 12 x x 3000mm |

| Lam 2 double wave | 122 12 x x 3000mm | |

| Lam 5 waves | 122 12 x x 3000mm | |

| Lam 2 high waves | 122 20 x x 3000mm | |

| Fake white paper | 157 10 x x 3000mm | |

| Dimensions of 3D PVC panels |

|

If you have any questions about plastic panels or need advice on designs, construction prices, material prices, and dealer policies, please call immediately. 0903 093 221 to receive advice. It can be seen that, with the development of printing technology, plastic panels will be the wall/ceiling material that anticipates all future trends.

Kim Hoa is an expert in interior and exterior decorative materials at Kosmos Vietnam. She has professional knowledge of interior design and loves finding creative ways to optimize space with simple construction decoration materials such as wood, stone, bamboo, brick and plastic.

Kim Hoa Regularly participate in seminars and exhibitions on interior decoration materials to update the latest trends, as well as to learn more about interior decoration materials. Meet interior and exterior designers, architects, and material experts to continuously learn. She also actively shares her knowledge and experience on social media channels such as Facebook, YouTube, Tiktok... with more than 100 thousand followers.

Mission of Kim Hoa not merely providing information, but also ensuring that All information posted is quality, has in-depth investment and is most useful to viewers.