Accessories consultation

Materials for making skeletons for wall panels

Skeleton is a necessary element when tiling plastic panels on damp, uneven walls. They are also an indispensable element when using ceiling plastic panels. So how many types of materials are used to make the frame for plastic wall panels? What are their characteristics and uses? All will be presented in detail shortly!

How many types of skeleton for plastic wall panels?

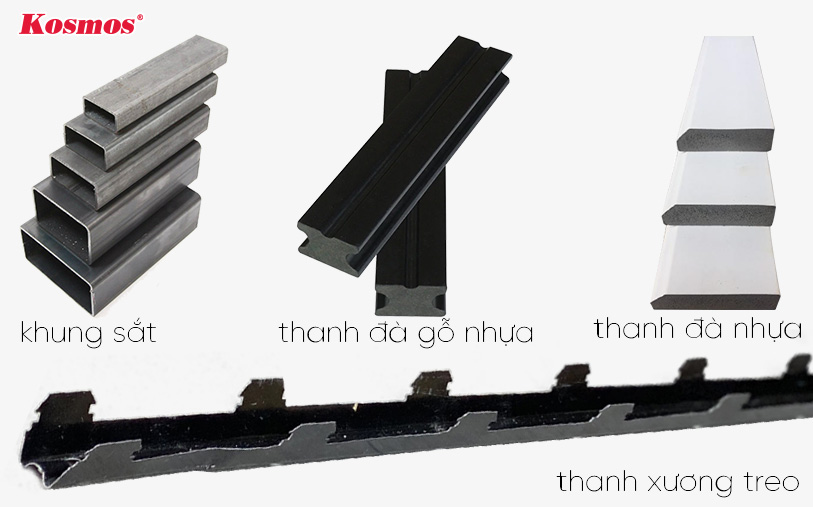

There are 3 types of frames for plastic wall panels: box iron, plastic wood and plastic. There is a special case of ceiling slats - interior ceiling decoration materials that must use a separate frame called "hanging bone bar”. The materials used to make the skeleton must meet two factors: sturdy and durable. Frame quality directly affects the lifespan of construction works.

Box iron skeleton – features and uses

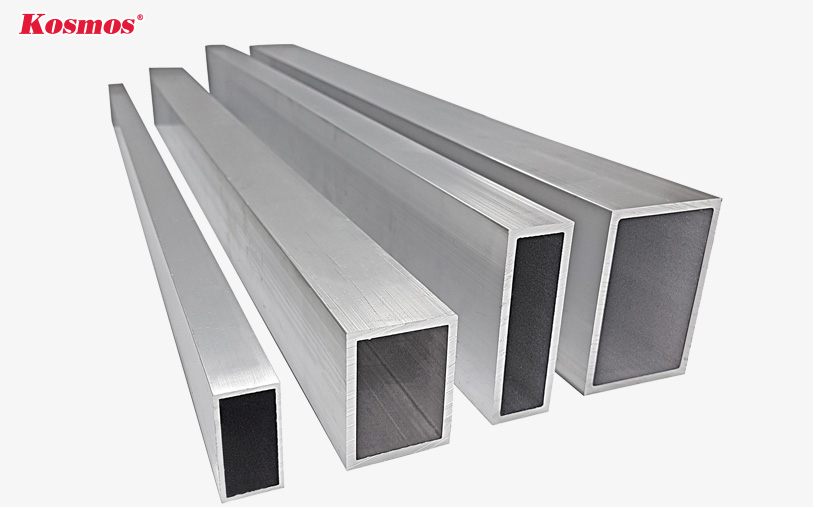

Steel Box It is a material widely used in the construction and mechanical product manufacturing industry. Box iron bars are machined into thick, hollow cubes 0.7 mm come 5.1 mm and has a length of up to 6m. Many people also call box iron as box steel, or call it by shape such as: square box iron (square box steel), rectangular box iron (rectangular box steel). There are two types of iron boxes on the market: black iron boxes and galvanized iron boxes.

Black box iron – Black box steel

Black box iron (black box steel) is a type of steel with a glossy black surface. The characteristics of black box steel are durable, good load-bearing, and less deformed, so it is widely used in construction projects such as: skeleton frames for interior and exterior decoration materials, scaffolding, roof frames, …

The disadvantage of black box iron is that it is easy to rust, so it is not suitable for long-term installation in outdoor areas or areas near sea water. We can apply more anti-rust paint to ensure the quality of the frame. On the other hand, manufacturers have launched galvanized iron boxes to overcome this drawback.

Galvanized iron box – Galvanized steel box

Galvanized iron box (galvanized steel box) is a type of iron and steel that can withstand all environmental impacts thanks to the zinc coating on the surface. The frame is made of galvanized box iron and can be used outdoors and on the coast because of its high anti-oxidation ability. In addition to the price of galvanized box iron being higher than black box iron, this material has many advantages such as:

- Tough, withstand strong force.

- Does not rust and is less susceptible to corrosion.

- The zinc coating does not shrink or crack.

- Save maintenance costs.

- The price of galvanized iron is not high.

- Ensure project longevity.

Plastic wooden fly bars – characteristics and uses

The material for making the skeleton from plastic wood is called plastic wood fly bar. This type of material is used to make frames (flying bars) for house decoration works. Plastic wood flywheel is a hybrid material between wood and plastic, so it is durable and does not lose quality when installed outdoors. There are two types of wooden plastic rafters, solid holes and hollow ones.

| Solid core plastic wooden fly bar | Hollow plastic wooden stick | |

| the size (width x length) | 40 mm x 2200 mm | 40 mm x 2200 mm |

| Thickness | 25 mm | 30 mm |

| Illustration |  |  |

Plastic fly bars – the material to make the frame for wall panels

Plastic beams can perform well as a skeleton for lightweight panels, used in interior areas such as: fluted wood imitation plastic panel, stone grain pvc,... This product has a thickness of 14 mm - width 40mm - length 2500 mm.

Features of Hanging Bones

Plastic panels can be wall and ceiling tiles and the frame material for both positions is the same. However, ceiling decoration materials such as slats need a special type of frame. The ceiling slats frame (hanging bar) is an accessory designed to fix the spokes. The hanging bone bar is an iron bar with anti-rust black paint. The 2 sides of the bone bar contain round holes for mounting screw mounts to the ceiling and lengths up to 3mm.

How to install an iron skeleton for wall / ceiling plastic panels

The skeleton acts as a support with plastic panels. We apply glue on the surface of the frame and then fix the plastic sheet on top. You can use more screws and stainless steel screws to fix more panels with locking lugs. How to install the skeleton for plastic wall panels - ceiling tiles are as follows:

Step 1: Locate the skeleton

The location of the skeleton is determined based on a carefully measured drawing or by agreement between the two workers and the owner. The horizontal bone bar is no more than 2 mm from the wall - ceiling. The vertical bar is fixed at both ends on the horizontal bar.

- Distance between the crossbars on the skeleton: 600 – 700 mm.

- Distance between longitudinal bars on skeleton: 1500 – 2000 mm.

Step 2: Fix the skeleton system

We fix the frame straight to the wall with short steel pieces (10x10x100 mm) and the mounts about 50mm. At the intersection of the vertical bar and the horizontal bar, we will catch the steel beard (or steel ti and iron expansion). Finally, when the skeleton has been assured of flatness and verticality, we dot weld the frame system with steel beard, cutting off the excess steel beard.

Summary

Skeleton As the spine of the construction of plastic wall panels, it needs certainty. You should avoid using wood to make skeletons because they will be changed by environmental factors. Kosmos Vietnam Joint Stock Company is a decorative material supplier that provides skeleton materials for plastic wall panels such as: galvanized iron, plastic wood beams and hanging bones.

Please visit Kosmos Vietnam Fanpage or hotline: (+84) 903.093.221 for more specific advice from customer service.

Kim Hoa is an expert in interior and exterior decorative materials at Kosmos Vietnam. She has professional knowledge of interior design and loves finding creative ways to optimize space with simple construction decoration materials such as wood, stone, bamboo, brick and plastic.

Kim Hoa Regularly participate in seminars and exhibitions on interior decoration materials to update the latest trends, as well as to learn more about interior decoration materials. Meet interior and exterior designers, architects, and material experts to continuously learn. She also actively shares her knowledge and experience on social media channels such as Facebook, YouTube, Tiktok... with more than 100 thousand followers.

Mission of Kim Hoa not merely providing information, but also ensuring that All information posted is quality, has in-depth investment and is most useful to viewers.

- What is a picture frame? The most beautiful picture frame samples

- Instructions for construction of wood plastic wall panels

- Latest price of insulation panels for walls, ceilings and partitions

- Price list of perforated aluminum ceilings - advantages and disadvantages?

- Is Kingdoor door review good? Classification and quotation

Related articles of interest:

- Galawood plastic wood newsletter

- Kosmos plastic wood newsletter

- Newsletter Kosmos

- Korean Wave Newsletter

- Newsletter fluted panel Kosmos

- Korean molding news

- Stone PVC Newsletter

- Laminate flooring newsletter

- Egger laminate flooring newsletter

- Galamax laminate flooring newsletter

- Kosmos laminate flooring newsletter

- Povar laminate flooring newsletter

- Robina Flooring Newsletter

- Newsletter Thaixin laminate flooring

- Plastic floor newsletter

- Newsletter plastic wall panels

- Newsletter of bamboo charcoal panels

- Bulkhead newsletter

- agents

- Accessories consultation

- Wiki - Interior and exterior trends

Accessories consultation

Top 6 types of plastic and wood glue that are currently extremely hot on the market

Wiki - Interior and exterior trends

Compare stainless steel 201 and stainless steel 304 - 5 ways to distinguish

Accessories consultation